The new culture club: Microfluidic cell culture device materials

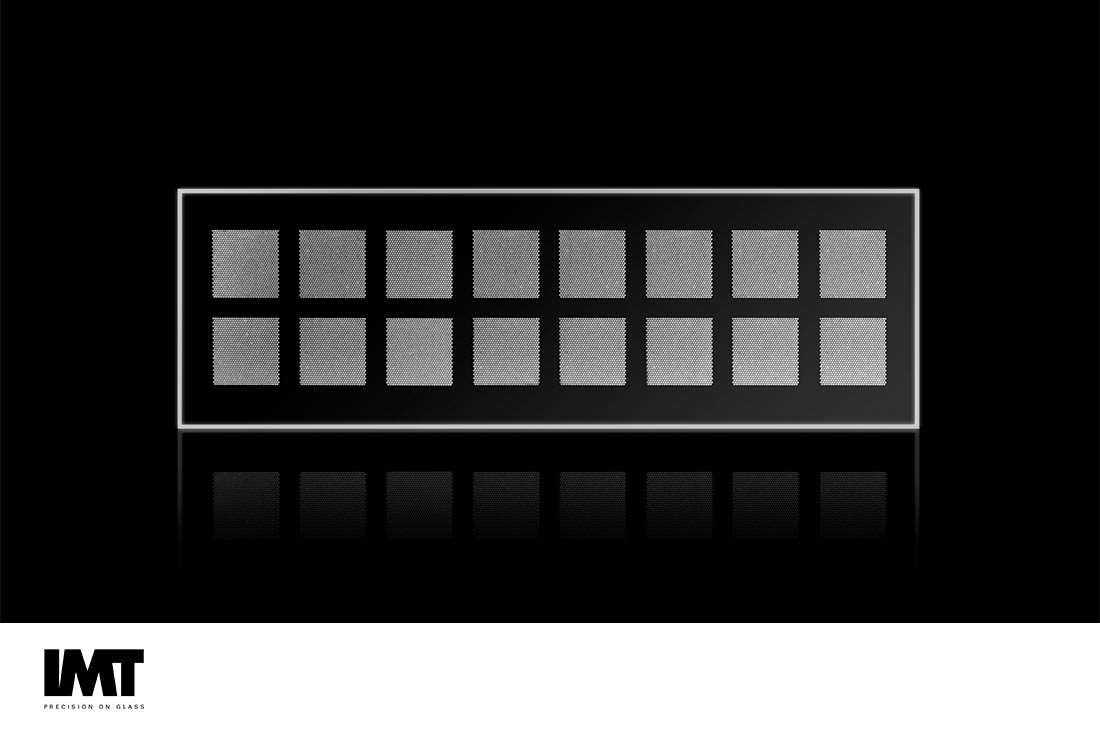

Microscope slide with isotropically etched cavities in glass to grow organoids [IMT].

Microfluidic cell culture device materials can be a challenge. Why bother?

Though cell-culture-on-a-chip for in vitro diagnostics applications lacks the three-dimensional advantages of an in vivo experiment, there are advantages. The planar platform can allow researchers to isolate cell function without interference from the complex environment in vivo and allow visualize them more easily. With the goal of accelerating drug discovery by providing responses that mimic in vivo responses, organ-on- a-chip applications rely more heavily on hybrid materials that can include a planar support for a three-dimensional scaffolding of an entirely different composition [1].

Cell culture-on-a-chip approaches also reduce animal care expenses and animal suffering. Many examples exist, including iCHIP (in-vitro Chip-based Human Investigational Platform) which reproduces four major biological systems vital to life: the central nervous system (brain), peripheral nervous system, the blood-brain barrier and the heart. This so-called “human-on-a-chip” being attempted by a team of scientists and engineers at Lawrence Livermore National Laboratory is a miniature external replication of the systems that comprise the human body. Their approach integrates biology and engineering with a combination of microfluidics and multi-electrode arrays [2].

However, depending on the cells, the media, and the phenomena one desires to measure or observe, the best material, configuration, and post-fabrication processing varies. Even the channel design can affect cell viability as some cells are more susceptible to shear stress than others [3]. Factors such as the fabrication complexity created by hybrid material insertion, in situ synthesis, or layering with the impact on cell viability based on gas permeability and protecting cells from inorganic and organic poisons are factors. A wide selection of materials, including silicon, glass, PDMS and polymers, have been combined with hydrogels, biopolymers and additive manufactured scaffolding using proteins and the organ cells themselves.

PDMS has often been used because of the favorable gas permeability, allowing for gases to be exchanged between the cells on a chip and the environment surrounding the chip. The breathable lung-on-a-chip illustrates the biomimetic attributes of PDMS. However, this gas and ion permeability can also result it unintended exposure to gases and ions that can compromise cell health as well.

Similarly, patterning substrates to locate cells on one region of a device has many advantages, but cells not meant to be in contact with a surface may eventually lose activity as the surface affects the cell shape and physiology. Depending on the assay, requirements for cell activity may vary from a few hours to a few days. Material interactions with cells may be less important if the interaction occurs after the cell behavior to be measured.

A successful commercialization of a PDMS organ-on-a-chip platform has been demonstrated by Emulate, Inc. (emulatebio.com/insight/). Emulate’s Organ-Chips — such as lung, liver, intestine, and brain — accurately recreate human biology and disease states. This is achieved by employing engineering principles to recreate the micro-environment experienced by cells in the human body by controlling the extracellular matrix, tissue interfaces, mechanical forces, immune cells, blood components, and biochemical surroundings [4].

Neuronal cells are often measured using electrodes, making the standardized patterning of electrodes on glass or silicon a reason to choose either material [3]. The ability to use indium tin oxide (ITO) electrodes that are transparent can be an advantage to using glass, as the cells can be monitored using a microscope, even when on an electrode surface.

Because of the desire to use optical methods, glass is often the best material. Fortunately, it is possible to use silane chemistry to modify the glass features for more favorable surface properties after a high -temperature bonding step to seal the device.

Even better, room temperature bonding techniques using UV adhesives can be employed [5]. UV-adhesives are well known in industry with verified biotoxicity and biocompatibility data and often implemented for biomedical applications.

Of course, often the best solution is to take advantage of the properties of each material, with optical features like ITO electrodes patterned on glass, polycarbonate as the base for additional sensing features, and PDMS forming the cell culture layer [6]. Also, the utilization of membranes as an isolation and cell culture layer integrated between glass wafers combined with pressure modulation of can provide a good alternative to PDMS circumventing issues of gas diffusion. More and more, it is the hybrid material devices that are able to overcome the challenges of the complexity of using live cells [7].

Works Cited

[1] C. Y. Chan, P.-H. Huang, F. Guo, X. Ding, V. Kapur, J. D. Mai, P. K. Yuen and T. J. Huang, "Accelerating drug discovery via organs-on-chips," Lab Chip, vol. 13, no. 24, pp. 4697-4710, 2013.

[2] Lawrence Livermore National Laboratory, [Online]. Available: https://www.universityofcalifornia.edu/news/human-chip-could-replace-animal-testing.

[3] N. Li, A. Tourovskaia and A. Folch, "Biology on a Chip: Microfabrication for Studying the Behavior of Cultured Cells," Critical reviews in biomedical engineering, vol. 31, no. 0, pp. 423-428, 2003.

[4] D. Huh, B. D. Matthews, A. Mammoto, M. Monoya-Zavala, H. Y. Hsin and D. E. Ingber, "Reconstituting Organ-Level Lung Function," Science, vol. 328, pp. 1662-1668, 2010.

[5] M. Serra, I. Pereiro, A. Yamada, J. L. Viovy, S. Descroix and D. Ferraro, "A simple and low-cost chip bonding solution for high pressure, high temperature and biological applications," Lab Chip, vol. 17, pp. 629-634, 2017.

[6] S. M. Bonk, P. Oldorf, R. Peters, W. Baumann and J. Gimsa, "Fast Prototyping of Sensorized Cell Culture Chips and Microfluidic Systems with Ultrashort Laser Pulses," Micromachines, vol. 6, pp. 364-374, 2015.

[7] X. Hou, Y. S. Zhang, G. Trujillo-de Santiago, M. M. Alvarez, J. Ribas, S. J. Jonas, P. S. Weiss, A. M. Andrews, J. Aizenberg and A. Khademhosseini, "Interplay between materials and microfluidics," Nature Rev Mat, vol. 2, pp. 1-15, 2017.