This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Thin films

Coatings: technologies and systems for mass production

Electron beam evaporation and thermal evaporation

Evaporation in a vacuum via electron beam evaporators or thermal vaporisers has come into use for coating optical components and substrates for lithographic processes. This technology allows for the production of a number of metallic coatings such as chrome, aluminium, gold, titanium, black chrome (low reflection chrome) and other metals of high quality and with a coating thickness of a few nanometres up to several hundred nanometres.

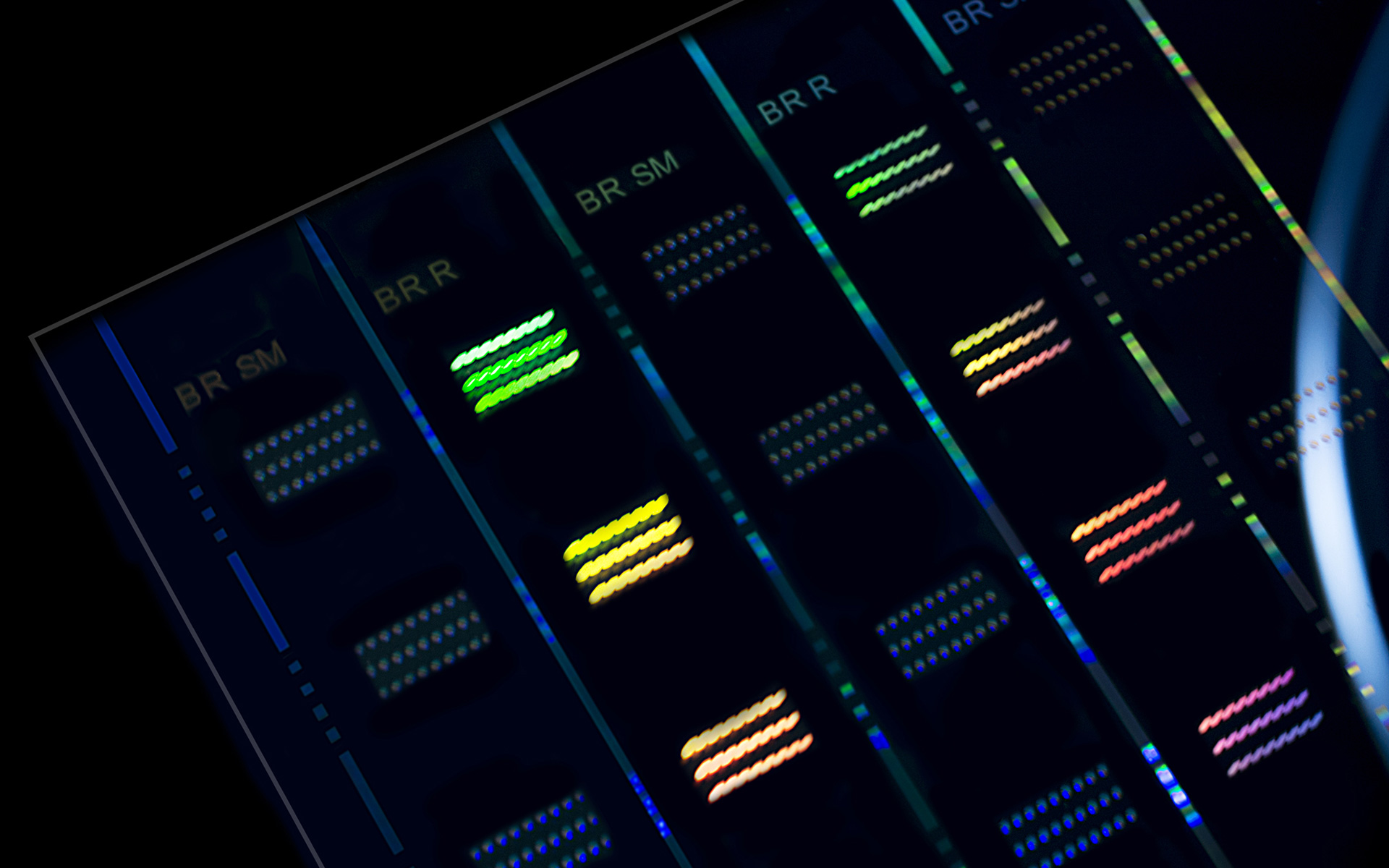

With the expansion of thermal evaporation and electron beam evaporation via substrate heating at 100 to 300°C or via a plasma source, it is also possible to produce optical coatings, known as interference coatings, of high optical quality. These fulfil a range of functions, including antireflection coatings, optical filters such as band-pass filters, UV or IR filters, colour filters, Fabry-Perot filters, beam splitters and dielectric mirrors.

Coating systems for PVD and magnetron sputtering

Format: 200mm-Wafer

Batch size: </= 16 Wafer

Substrate: Fused Silica, B270, Borofloat, D263, other materials on request

Thickness: >0,3 mm